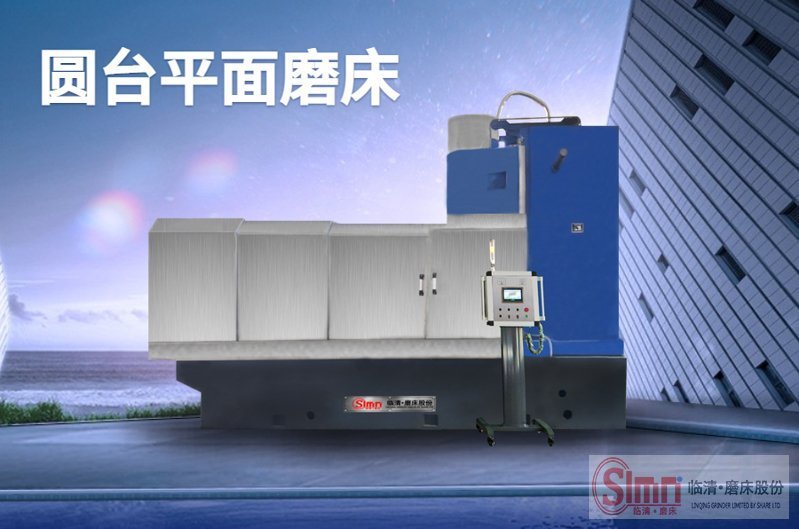

立軸圓(yuan)臺(tai)磨床是(shi)機械制(zhi)造過程中常用的磨床設備之(zhi)一(yi),然而當使用過程中發(fa)現(xian)磨床沒磁(ci)性時(shi),操(cao)作(zuo)人員須要及時(shi)采取(qu)有(you)(you)效措施。首先(xian)應該檢(jian)查(cha)磨床上的磁(ci)性鐵(tie)是(shi)否(fou)有(you)(you)損壞(huai)或(huo)松(song)動,以及自磁(ci)鐵(tie)和控制(zhi)電路是(shi)否(fou)正常工作(zuo)。如果(guo)磁(ci)性鐵(tie)出(chu)現(xian)了損壞(huai)或(huo)松(song)動,則(ze)應該及時(shi)進行更換或(huo)緊固(gu)。如果(guo)自磁(ci)鐵(tie)沒有(you)(you)正常工作(zuo),可(ke)以檢(jian)查(cha)電源(yuan)是(shi)否(fou)正常供電,如果(guo)電源(yuan)工作(zuo)正常,則(ze)需要檢(jian)查(cha)磁(ci)性線(xian)圈的連(lian)接是(shi)否(fou)緊固(gu),接線(xian)是(shi)否(fou)正確。

如(ru)果以上(shang)檢查都(dou)沒有(you)發現(xian)(xian)問題(ti),那(nei)么有(you)可能是(shi)磨(mo)床(chuang)上(shang)的磁(ci)性(xing)(xing)(xing)(xing)鐵(tie)(tie)(tie)和(he)磁(ci)性(xing)(xing)(xing)(xing)線(xian)圈(quan)(quan)出(chu)現(xian)(xian)了磁(ci)化消失的情況,需要(yao)重新磁(ci)化。重新磁(ci)化的方法如(ru)下(xia):將(jiang)磨(mo)床(chuang)插上(shang)電源,然后(hou)將(jiang)磁(ci)性(xing)(xing)(xing)(xing)鐵(tie)(tie)(tie)陣(zhen)列(lie)旋轉至磁(ci)性(xing)(xing)(xing)(xing)線(xian)圈(quan)(quan)下(xia)方,使磁(ci)性(xing)(xing)(xing)(xing)鐵(tie)(tie)(tie)接觸(chu)磁(ci)性(xing)(xing)(xing)(xing)線(xian)圈(quan)(quan)。接下(xia)來,將(jiang)磁(ci)性(xing)(xing)(xing)(xing)線(xian)圈(quan)(quan)和(he)自磁(ci)鐵(tie)(tie)(tie)連通電源,然后(hou)緩慢旋轉磁(ci)性(xing)(xing)(xing)(xing)鐵(tie)(tie)(tie)陣(zhen)列(lie),直到磁(ci)性(xing)(xing)(xing)(xing)鐵(tie)(tie)(tie)陣(zhen)列(lie)所(suo)有(you)磁(ci)性(xing)(xing)(xing)(xing)鐵(tie)(tie)(tie)都(dou)與磁(ci)性(xing)(xing)(xing)(xing)線(xian)圈(quan)(quan)接觸(chu)并被(bei)磁(ci)化。這(zhe)樣就(jiu)可以使磨(mo)床(chuang)恢復磁(ci)性(xing)(xing)(xing)(xing),重新開(kai)始工作了。

當使用立(li)軸(zhou)圓臺磨床時(shi)發現沒有(you)磁性(xing)時(shi),不要(yao)慌(huang)張(zhang),要(yao)及時(shi)采取有(you)效措(cuo)施(shi)進(jin)行檢(jian)查和修(xiu)(xiu)復。只要(yao)我們(men)仔細檢(jian)查和耐心修(xiu)(xiu)復,就(jiu)可以讓(rang)磨床恢復正常工作狀態,為機(ji)械(xie)制造過程提供保障(zhang)和支持。